Why are Dielectric Materials Used in PCB Instead of Insulators?

PCB’s can be manufactured from many types of materials. The reason they use a dielectric material in some because of an insulator is because of circuits that deal with high power radio frequencies. The dielectrics better insulate the circuits from the high power radio frequencies. Below is an article off of the internet that explains some of the materials used.

PCB Substrates – Printed Circuit Board Materials, FR-4

Insulating Backbone

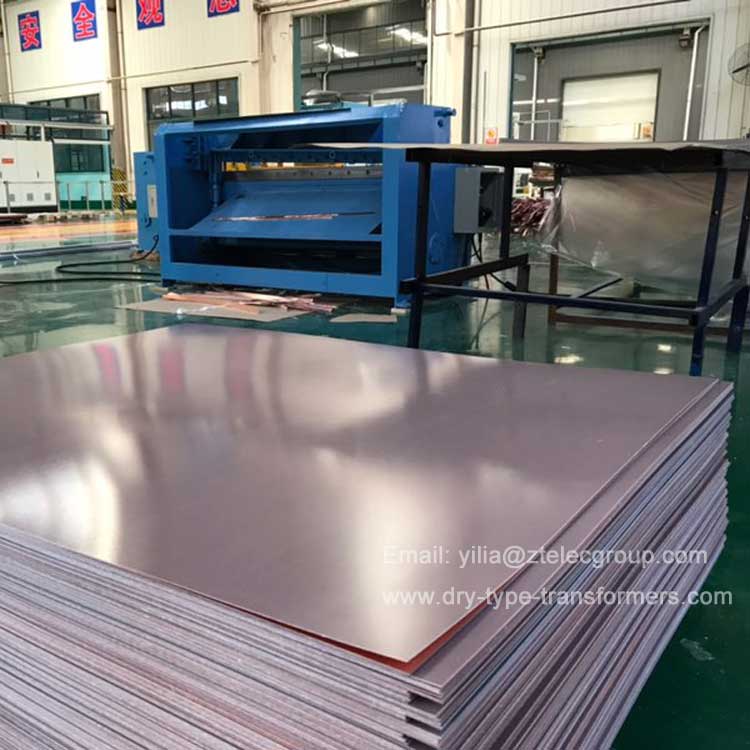

PCBs consist of two basic parts: a substrate (the board) and printed wires (the copper traces).

Multi-layer boards require substrates that separate the various layers.

The substrate provides a structure that physically holds the circuit components and printed wires in place and provides electrical insulation between conductive parts.

A common type of substrate is FR-4, which is a fiberglass-epoxy laminate. It is similar to older types of fiberglass boards but is flame resistant.

Substrates are also made from Teflon, ceramics, and special polymers.

PCB Substrates are specialized materials that do not conduct electric currents.For this purpose, they serve as a laminated electrical insulator between circuitry,An electrical insulator is a material whose internal Electric charge do not flow freely, and which therefore does not conduct an under the influence of an Each layer of circuitry, consequently, is connected through plated through holes to connect traces on opposite layers.