3240 epoxy board and FR4 epoxy board are the two most common epoxy board in the market. What’s the difference between them?

The adhesive used in 3240 is epoxy resin. Phenolic material was used as curing agent. Temperature tolerance is generally 155 degrees. Good machining performance .It is also suitable for transformer and transformer oil. Generally, the density does not exceed national standard 1.9. In order to save costs, some manufacturers will use fillers such as talcum powder in the production process. Their density will increase greatly. Of course, it also reduces the electrical performance. It is suitable for general insulation works only.

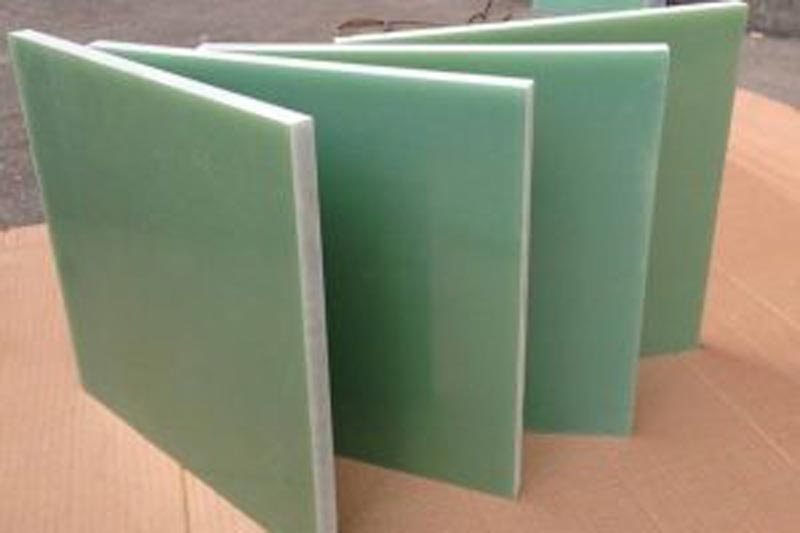

FR4 also USES epoxy resins, but it is not phenolic as a curing agent. It is solidified at high temperature and its temperature resistance is generally more than 180 degrees. Mechanical properties are very strong which suitable for electronic circuit board, copper clad board. The base material is all muslin and electronic fiber cloth. Its density is generally 1.85. FR4 is an improved product of 3240 epoxy plate with good flame retardant performance. The flame retardant performance of FR4 epoxy board conforms to the national ul94v-0 standard. FR4 is natural green . Most of the colors are not very uniform.FR4 has good dimensional stability and tolerance control in the pressing process is much better than 3240.FR4 has the function of natural extinguishing in case of fire.