What are the Differences Between FR-4 and CEM-3 Epoxy Boards in Terms of Materials and Properties

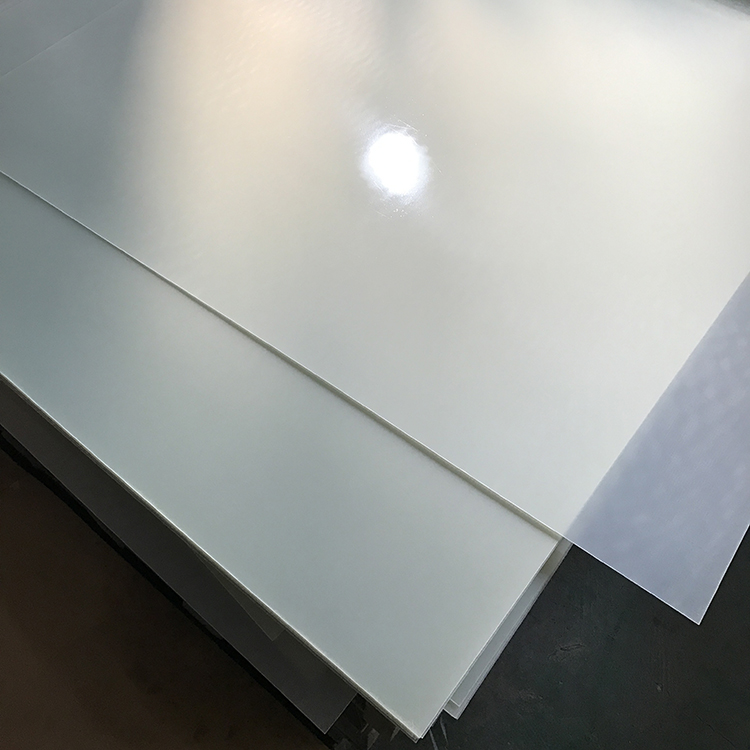

When using double-sided or multi-layer substrate materials for electronic products, FR-4 was the most common in the early years. In recent years, CEM-3 has been widely used in Japan to replace FR-4. CEM-3 is a new substrate material for printed circuit boards developed on the basis of FR-4. When using double-sided or multi-layer substrate materials, FR-4 is the most popular in the early years.

In recent years, CEM-3 has been widely used in Japan to replace FR-4. CEM-3 is a new type of printed circuit board material developed on the basis of FR-4. Its use is in double-panel. It has already exceeded FR-4, accounting for about 55% of the market.

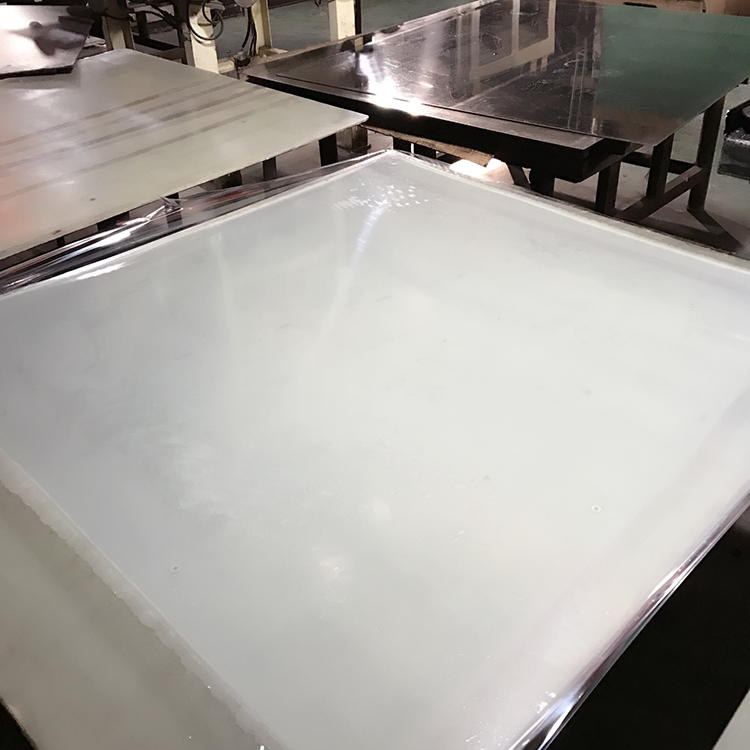

CEM-3 uses glass cloth and glass mat composite substrate in raw materials, not pure glass cloth, and FR-4 is laminated with copper foil and glass fiber cloth impregnated with flame retardant epoxy resin. The two are very similar in the production process. Both vertical gluing and horizontal gluing can be used. In order to better improve the performance of CEM-3, a certain amount of filler can be added to modify it to meet different thickness requirements. Different standard weight glass mats can be used to meet different thickness requirements.