Use of Electric Bakelite Processing Parts

Electric bakelite, many people will think that it is made of wood when they hear this name. Actually, it is a composite material, but the name of the wood is the name. The raw material for its manufacture is phenolic resin and cotton paper. The cotton paper is pre-impregnated with phenolic resin and then laminated according to the specified

thickness, and then pressed and solidified at a high temperature. After the electric board is produced, it needs to be machined and shaped into the required shape. It is used in various places. This article talks about the use of the board.

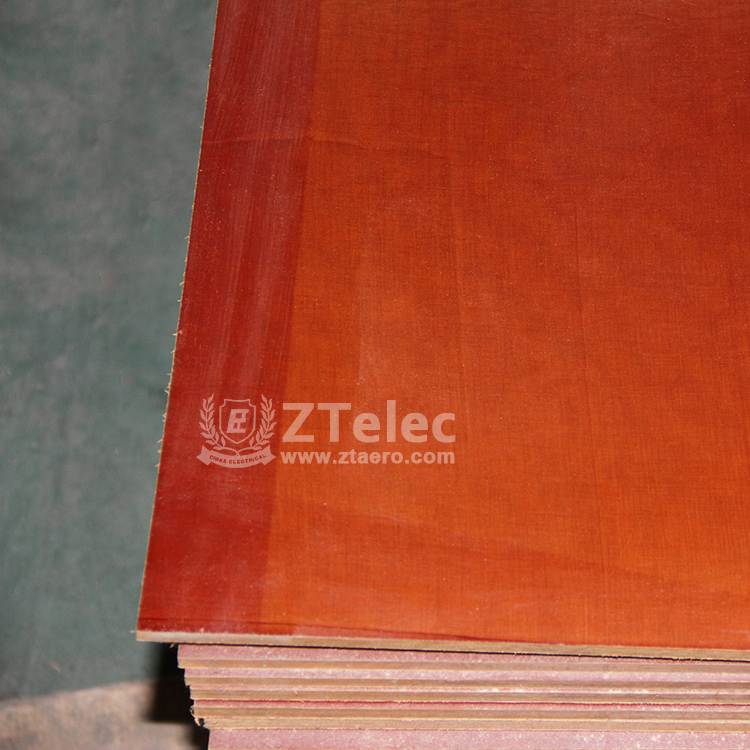

There are many uses for electric wood processing parts, mainly used in electrical and electronic fields, as insulating materials, such as manufacturing of drilling machine covers, polishing pads, switchboards, copper plates, transformers, and PCBs. In addition, it can also manufacture combs, auto parts, compasses, mechanical parts and so on. The bakelite is available in a variety of colors, including reddish brown, brown, black, and orange. The performance is also very good, with a specific gravity of 1.45. Low warpage, good machinability, good electrical performance, and a temperature range of -40 to 100 °C. This paper laminate is the most versatile and most used industrial laminate in the world. Although the performance is slightly worse than that of the epoxy board, the price is low and it is very popular.

Electric wood processing parts are widely used and have good performance. If you need to welcome ZTELEC GROUP to order, to process drawings, proofing is free. CNC computer control, high product accuracy and short delivery time. In addition to bakelite, we also have epoxy, phenolic, synthetic, acrylic and other products, the same quality. Click on the online consultation on the webpage to contact customer service to ask questions.