Twenty Kinds of Plastics and Their Properties—(7) PC/ABS

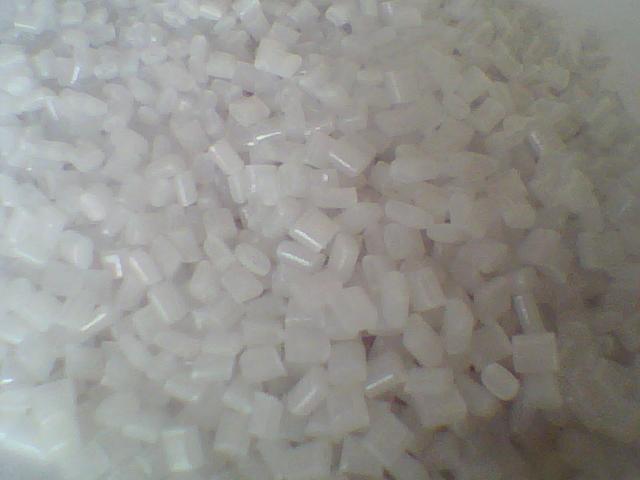

7.PC/ABS polycarbonate and acrylonitrile butadiene styrene copolymer and mixture

Typical application range:

The shells of computers and commercial machines, electrical equipment, lawn and gardening machines, automobile parts (dashboards, interior decorations, and wheel covers).

Injection molding process conditions:

Drying porcess: the drying process before processing is necessary. The humidity should be less than 0.04%. It is suggested that the drying condition is 90~110 °C, 2~4 hour.

Melting temperature: 230~300 °C.

Mold temperature: 50~100 °C.

Injection pressure: depends on the plastic part.

Injection speed: as high as possible.

Chemical and physical properties:

PC/ABS has the comprehensive characteristics of both PC and ABS. For example, the easy processing characteristics of ABS and the excellent mechanical properties and thermal stability of PC. The ratio of the two will affect the thermal stability of the PC/ABS material. The mixture of PC/ABS also shows excellent flow characteristics.