Product introduction

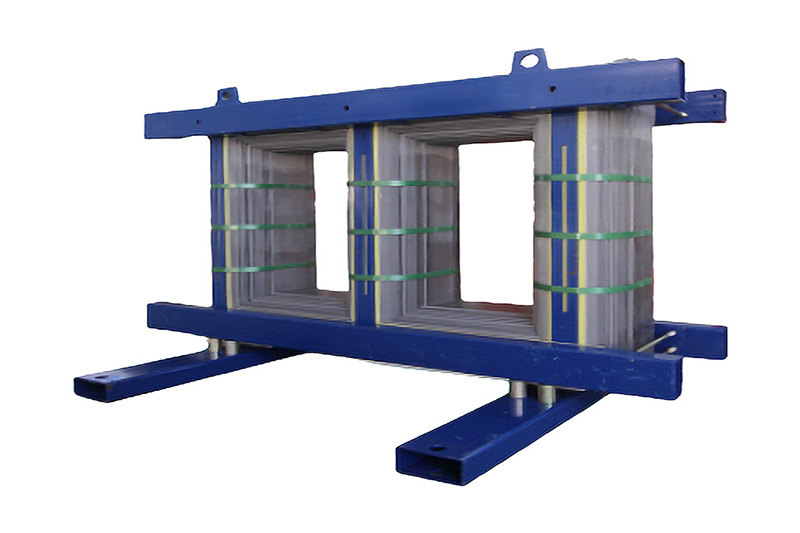

This product utilizes the latest bending fittings, which feature minimal components, high processing accuracy, precise positioning, easy assembly, and simplified surface treatment and painting processes.

Product Features:

1.The silicon steel sheets are processed using advanced intelligent production lines, resulting in high processing accuracy, minimal burrs, and high efficiency.

2.Emphasis on craftsmanship reduces external stress on the silicon steel throughout the entire process from raw materials to finished products, lowering the manufacturing process coefficient of the iron core and effectively ensuring product performance and quality.

3.Full sequence laminating method is adopted, offering three, five, or seven-step laminating processes based on different material and product requirements to provide differentiated solutions for customers.

4.High-strength steel is used for the fittings, and different steel materials can be provided based on customer requirements. CNC bending ensures high mechanical strength, precise dimensional positioning, and a sleek and aesthetically pleasing appearance.

5.The core column and lower yoke are secured using brushing and painting processes, enhancing the mechanical performance of the iron core. The materials used are environmentally friendly, safe, and free from irritating odors.

Technical Parameters:

| No. | Test items | Standard requirements | Actual data |

| 1 | Seam | ≤1.0mm | 1.0mm |

| 2 | No-load loss | PO≤553W | 540W |

| 3 | Window diagonal | ≤2.0mm | 1.2mm |

| 4 | Insulation resistance | Iro.n core to ground insulation resistance 5M2 |

≥5MO |

| 5 | Stem | Verticality≤(2/1000)mm | ≤(2/1000)mm |

| Curvature≤(1.5/1000)mm | ≤(1.5/1000)mm | ||

| 6 | Lamination thickness | Main stage:60±1mm | 60mm |

| Total stack thickness:260±1mm | 260mm | ||

| 7 | Window height and width | Window height:317±1mm | 317mm |

| Window width:185±1mm | 185mm | ||

| 8 | Clamp size | Strictly implemented in accordance with the technical agreement,non- standard clamps implemented in accordance with the national standard dimensional tolerance (C-level roughness) | Passed |

| 9 | Foot insulation | Laminated wood:32.5±0.5mm | 32.5mm |

| Pressboard:6±0.5mm | 6mm | ||

| 10 | Standard part size | Strictly implemented in accordance with the technical agreement, non- standard parts implemented in accordance with the national standard dimensional tolerance (C-level roughness) |

Passed |

| 11 | Overall appearance | Strictly implemented in accordance with the technical agreement,non- standard clamps implemented in accordance with the national standard dimensional tolerance (C-level roughness) | Passed |

Application :

Dry-type transformers

Phase shifting transformers

Oil-filled transformers

Single-phase transformers