The description of three-dimensional coiled iron core transformer

Three-dimensional coiled iron core transformer is an energy-saving power transformer. It is composed of three winding cores of the same geometric size which are assembled in a triangular three-dimensional arrangement and a three-dimensional coiled iron core as the magnetic circuit. The three-dimensional coiled iron core transformer creatively reforms the laminated magnetic circuit structure and three-phase layout of traditional power transformers to optimize product performance. For example, the three-phase magnetic circuit is completely symmetrical, the power saving effect is significant and the noise is greatly reduced, and the heat dissipation and overload capacity are improved.

The features of three-dimensional coiled iron core transformer

1.Low loss

According to the current international GB / T6451-2015 “Three-phase oil-immersed power transformer technical parameters and requirements” capacity of 30-1600kVA, the three-dimensional coiled iron core transformer reduces the average no-load loss by 50% and the average load loss by 30%. The RL series no-load loss has dropped by 30% on average, and the load loss has dropped by 25% on average.

2.Low no-load current

Due to the excellent material and winding processing characteristics of the coil core, the no-load current is significantly reduced. According to the current national GB / T6451-1999 and S13-M.RL series, the no-load current has decreased by 75% on average; the S11-M.RL series has the average no-load current decreased by 75%.

3.Low running noise

According to noise standard, the noise of three-dimensional coiled iron core transformer are reduced by about 7-9dB.

4. strong short-circuit resistance

The three-dimensional coiled iron core transformer body is formed into a triangular prism shape as a whole, and pull screws are arranged around and in the center which are integrated with the upper and lower iron yoke insulation and laminated wood blocks that can effectively resist the axial and radial mechanical stress during a sudden short circuit.

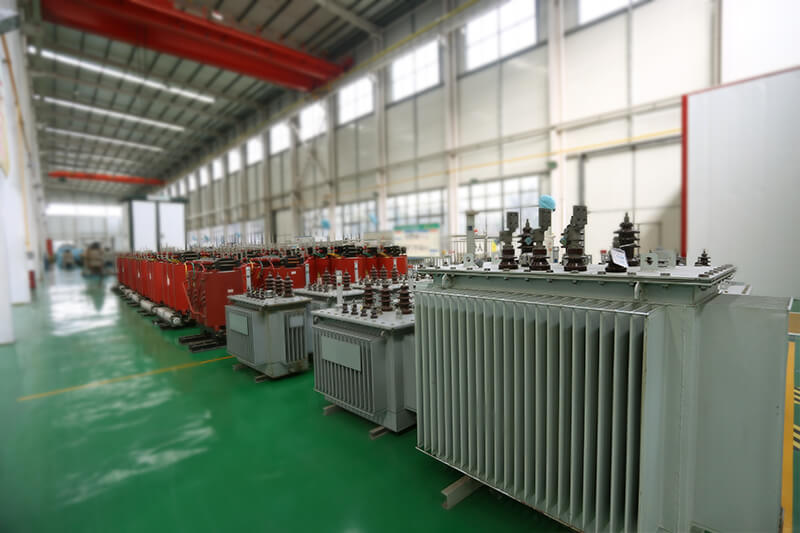

The structure of three-dimensional coiled iron core transformer

1.Iron core

The material performance is not less than 30ZH110 cold-rolled silicon steel sheet; the three-phase three-column three-dimensional symmetrical structure has the most balanced three-phase magnetic circuit; each group (coil) core sheet is wound by a thin steel strip on a dedicated core winding machine with uniform pressure compact. Iron core frame of three-dimensional coiled iron core transformer is vacuum annealed to eliminate stress and improve electromagnetic performance. the surface of the iron core is coated with epoxy paint to prevent moisture and solidify.

2.Winding

Paper-coated copper flat wire made of low-oxygen copper or QQ-2 acetal enameled round copper wire; low-voltage coils are double-layer or four-layer round copper or new spiral, or foil. The high-voltage coil is a multi-layer cylindrical type. The coil oil channel is a corrugated structure, and the interlayer insulation is double-sided adhesive paper; the low-voltage and high-voltage surfaces are wound with epoxy semi-adhesive glass fiber tape to increase mechanical strength.

3. Body and lead

Insulating cardboard is used to make the upper and lower iron yoke insulation. Laminated wood is used to make the balance pad insulation. laminated paper board of three-dimensional coiled iron core transformer is used as the lead frame. All fasteners are lock nuts that are effectively locked.

4, fuel tank

A fully sealed corrugated oil tank with a triangular structure is provided with corrugated fins in three phases to ensure heat dissipation and compensate for the expansion and contraction of the oil volume due to changes in oil temperature. An oil level gauge with a pressure relief valve is installed on the cover surface to facilitate refueling Observe the oil level, and release the pressure safety protection in the event of an overvoltage in the three-dimensional coiled iron core transformer.