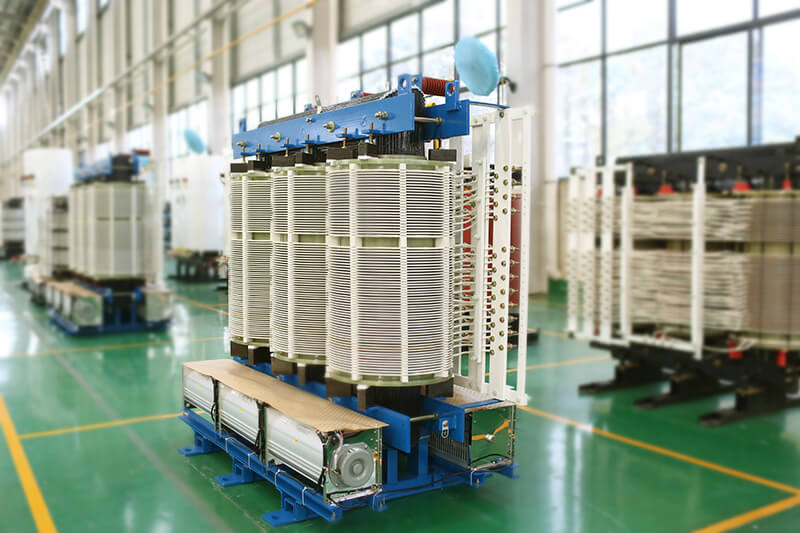

The installation of dry-type transformers

The installation of dry-type transformers is an important part of dry-type transformers. Dry-type transformers also require certain knowledge and technology during the installation process. Only the dry-type transformers are installed flexibly can the dry-type transformers be safe and stable run.

Preparations for the installation of dry-type transformers The installation of large-scale electric dry-type transformers has certain difficulties, mainly referring to the installation of electric dry-type transformers with a voltage of more than 110 kV and a weight of more than 100t. The preparation work is in place.

1. Make sure that the dry-type transformer that is not installed and the location of its constituent parts are set, and its storage method is also clear. A proper dry-type transformer unloading method should be selected, and at the same time that measures for its delivery to the construction site should be clarified. Before the installation work officially begins, the preparation of dry transformer oil related to the dry type transformer to be installed must be implemented. The protection of the actual position of the combined transformer must be put in place to lay the foundation for the safety of the construction. Before the installation work officially begins, the preparation of related equipment should be implemented to ensure the smooth installation of dry-type transformers. To carry out the relevant planning work in place, choose the appropriate dry-type transformer model, and at the same time clarify the installation work procedures. Specify the time required for installation work in advance, determine the amount of work, and implement the project budget.

2. Installation steps of dry-type transformers For the installation of large-scale electric dry-type transformers, special technical personnel should be arranged to take charge of their specific installation work. In some special cases, the unit’s technical staff can also perform the installation work.

During the specific installation process, other relevant departments should participate in the installation work together, such as the construction department, etc. and the installation work should be monitored and the test should be completed. The installation engineering procedures are mainly reflected in the following aspects: first, to complete the installation of accessories related to power dry-type transformers such as oil pillows, coolers, etc . To ensure the normal implementation of the next process Before the implementation of vacuum extraction and the removal of nitrogen and oil injection. It is necessary to effectively solve the problem of residual oil in the tank, especially the loss value of residual oil is outside the industry standard range which will affect the construction quality of the next process, so residual oil treatment should be implemented in place. vacuum oil injection work should be done well. The installation work of the remaining components should be put in place such as: risers, etc . After all the work of dry-type transformer installation is finished To implement vacuum pumping, the vacuum pumping time must be maintained for 24 hours and then the oil injection should be started. The oil injection and deflation should be performed synchronously until the oil is full and overflows and the entire installation is completed.