The glass is easy to fragile and it is not suitable for structure. When we pull glass into threadlet, the strength will increase a lot and become soft. The diameter of fiberglass get smaller, the strength will increase. So the application of fiberglass is more wider than other fiber. The fiberglass is equipped with following characteristic. They are high tensile strength, high elasticity coefficient, high impact strength, chemical resistance, low water absorption, good heat resistance. All in all it is cheap.

FRP is fiberglass reinforced plastic in short. Generally refers to glass fiber reinforced unsaturated polyester, epoxy resin and phenolic resin matrix. Reinforced plastics made of glass fiber or its products as reinforcing materials are called glass fiber reinforced plastics or glass fiber reinforced plastics. Because the resin breed that USES is different, so we call them polyester fibreglass, epoxy fibreglass, phenolic fibreglass to say. Light and hard, non-conductive, high mechanical strength, less recycling, corrosion resistance. It can replace steel to make machine parts and car, ship shell and so on.

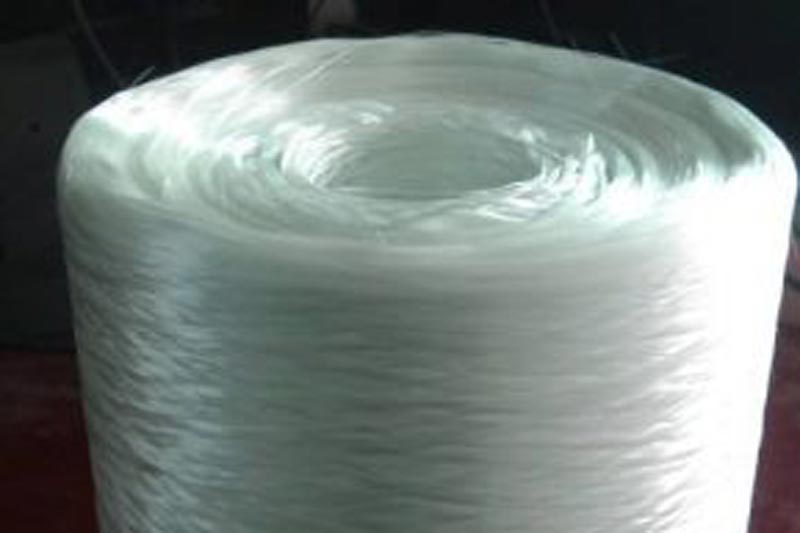

Glass fiber can be woven into glass fiber cloth, glass fiber cloth after epoxy resin curing is glass steel. This is a different stage of the product. Fiberglass is a raw material. Fiberglass is a finished product. Different shapes of fiberglass products, layer upon layer of glass silk cloth, coating epoxy resin.