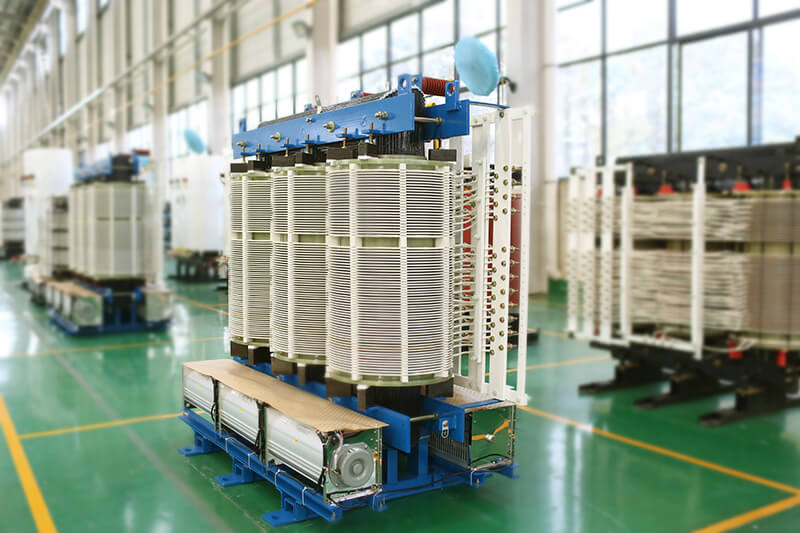

The features of of SCB10 dry-type transformer

SCB10 dry-type transformer is safety, flame retardant, no pollution with maintenance-free and low comprehensive operation cost. SCB10 dry-type transformer has good moisture resistance that can run under 100% humidity.

SCB10 dry-type transformer can easy to install that can be installed in harsh environment.

SCB10 dry-type transformer has low loss, small partial discharge, low noise and strong heat dissipation ability with strong overload capacity and strong short-circuit resistance;

SCB10 dry-type transformer is equipped with a complete temperature protection control system to provide reliable guarantee for the safe operation of the SCB10 dry-type transformer.

SCB10 dry-type transformer structure

1. Iron core of SCB10 dry-type transformer structure

The core of SCB10 dry-type transformer structure is made of high-quality, high-permeability, low-loss, cold-rolled grain-oriented silicon steel sheet. The 45 ° C full-material seam stepped stack structure. The core is tied with high-strength insulating tape, which effectively reduces no-load loss, wears current and the core. Noise, the surface of the iron core is sealed with insulating resin to prevent moisture and rust, and the clips and solid parts are surface treated to prevent rust.

2. Pouring coil

a. Main materials and characteristics

The coil is wound with copper foil, the interlayer insulation material is a polyester film produced by DuPont of the United States, and then filled with epoxy resin with filler from Switzerland TOBLY and Italy BP2. The glass fiber is reinforced, and its expansion coefficient is similar to that of a copper conductor. Has good impact resistance, resistance to temperature changes, resistance to cracking, glass fiber and epoxy phase grease, silicon powder are self-extinguishing, will not continue to burn, and will not produce toxic gases to pollute the environment.

b. Manufacturing process of SCB10 dry-type transformer structure

The coil is wound on a high-precision foil winding machine. Glass fiber is laid on the outer layer of the coil during winding. After the coil is wound, it is vacuum-dried. The entire casting and curing process is controlled by a microcomputer and is strictly performed according to the curing. The terminal monitors and is automatically adjusted by the computer according to the situation. The precision equipment strictly controls the manufacturing process, so that the casting coil is free of bubbles and cavities, and the partial discharge is small.

3.Foil coil of SCB10 dry-type transformer structure

For low-voltage and high-current coils, the short-circuit stress is greater when short-circuited and the number of low-voltage turns is smaller. The larger the low-voltage current, the more prominent the imbalance problem of the ampere-turn when using a wire is wound and the heat dissipation effect is also not good. Winding. There is no axial turns and axial winding helix angles for foil winding. The high and low voltage windings are balanced with ampere-turns. The axial stress is small during short circuit. It is easy to set up multilayer air ducts in technology to solve the heat dissipation problem. Lead welding on the foil winding machine adopts argon shielding welding, high precision, low welding resistance, no external welding process. D279 insulation is used between the winding layers, and the back end is sealed and cured with resin after winding.

4.Enclosure transformer of SCB10 dry-type transformer structure

SCB10 dry-type transformer structure can be configured with different protection levels according to different operating environments. The protection level of IP00 is a non-enclosure product. The IP housing can prevent solid substances larger than 12mm from entering. It is suitable for indoor installation. The IP23 protective housing has the characteristics of IP20 housing. It can prevent the inflow of water drops within an angle of 60 ° C from the vertical line, and is suitable for outdoor installation. The material of the IP20 housing generally has a steel plate profile structure. An aluminum alloy structure and a stainless steel structure.

5.Temperature display control system of SCB10 dry-type transformer structure

SCB10 dry-type transformer structure temperature protection adopts the principle of PT100 linear platinum resistance sensor, LED temperature display with temperature setting, save high temperature value, automatically send out alarm trip signal, automatic / manual start and stop fan function. Due to the principle of PT100 linear platinum resistance sensor. It has the advantages of high accuracy, stability and reliability.

6. Air cooling system of SCB10 dry-type transformer structure

Adopt axial flow fan, with low noise, large air volume, low energy consumption, uniform cooling, beautiful appearance, simple installation and reliable operation.