On the “Overload Capacity” of the Transformer

We know that overload capacity is related to loss, rated temperature, rated operating point, capacity margin, heat dissipation area, product structure, insulation grade and other factors. The national standard GB/T 17211-1998 “dry power transformer load guide” standard mentioned that the determination of the ratio of Z for the hot and average temperature rise ratio of dry change has a great influence on its overload capacity. Because the national standard GE/T 17211-1998 is the equivalent of the IEG-726 standard, the value of Z is not more than 1.25 according to the IEC-726 standard. Through the investigation on various dry-type transformer in China Manufacturer’s data collection, we learned that the casting structure nowadays mainly adopts dry type ring casting thin insulated wire, easy to energy surface coil. In addition, according to the size of the transformer, an axial heat dissipation duct with bidirectional heat dissipation can be arranged in the inner layer of the coil.

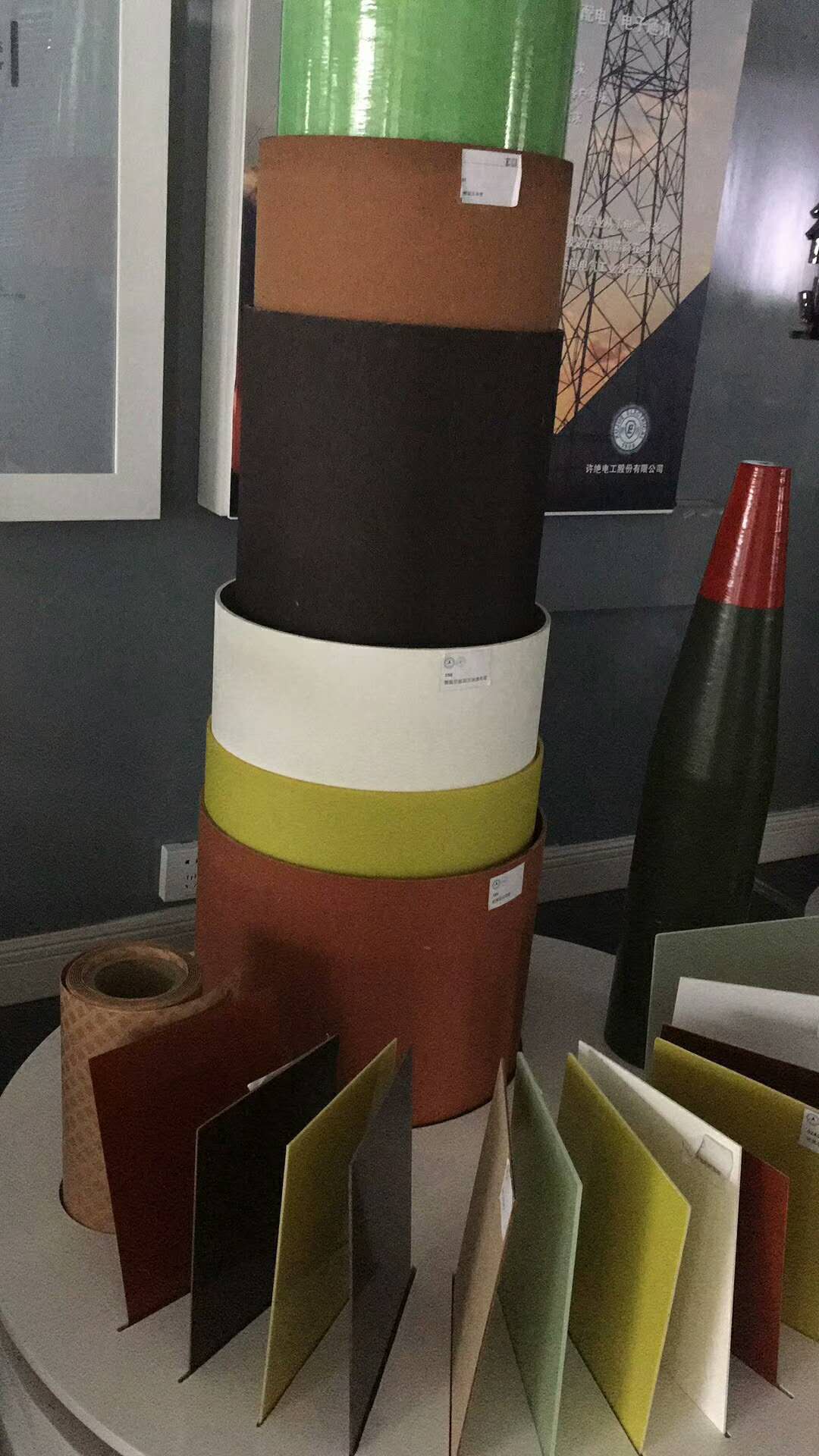

The Z value of epoxy resin castable dry is generally about 12, which is relative to the standard Z which is less than or equal to 1.25. But for the NOMEX paper insulation varnish manufacturers become dry, although unable to provide the exact Z value and numerical basis, but according to foreign experience, NOMEX paper insulation varnish dry type in the overload capacity should be better than the epoxy resin pouring dry. The reason is that the thermal margin of products from grade C insulation materials (220 degrees Celsius) to H class (180 degrees Celsius) has only been utilized before. But this conclusion must have a premise, it is dry and manufacturers must ensure that all coil insulation pads, and stays and other components are must use NOMEX paper products belong to class C insulated.