Insulating Paper Materials Commonly Used in Power and Transformers

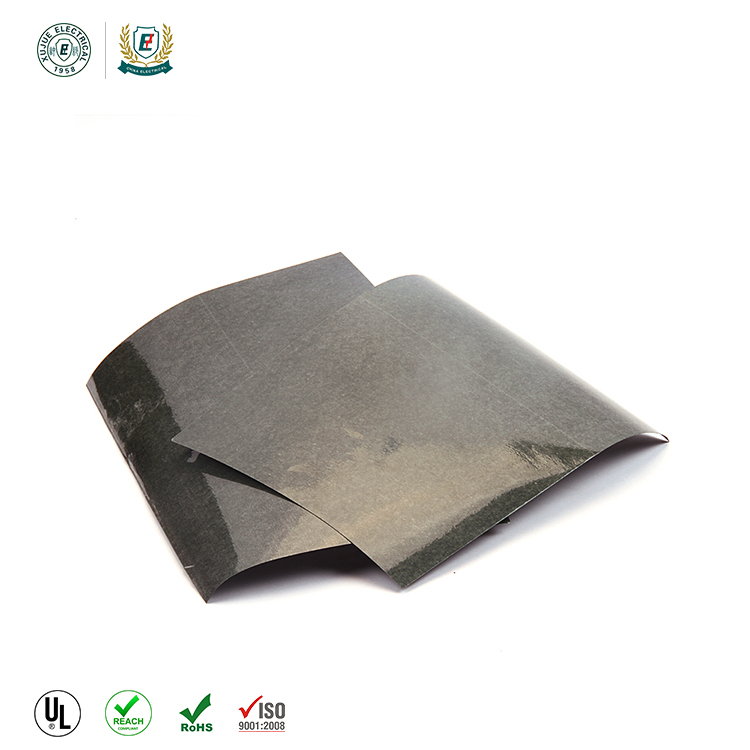

Insulating paper is a whole made of two or more layers of resin-impregnated fibers or fabrics which are laminated and heat-pressed. It can be a plate, tube, rod or other shape. Laminates can be processed into a variety of insulation and structural components and are widely used in motors, transformers, high and low voltage electrical appliances, electrical instruments and electronic equipment.

With the development of the electrical industry, high insulation. Insulated crepe paper with high strength, high temperature resistance and adaptability to various environments. Copper-clad laminates for printed circuits are also rapidly evolving due to the needs of the electronics industry. China’s electrical and electronic laminates have gradually developed after liberation. China’s thermosetting laminates have formed a relatively complete series.

The properties of insulating paper depend on the substrate and adhesive as well as the molding process. The laminates can be classified into the following two types according to their compositions, characteristics, and heat resistance.

(1) Organic substrate insulation paper – wood pulp insulation paper, cotton fiber paper, cotton cloth, etc. as reinforcing materials. The long-term use temperature can reach 120 ° C, and synthetic fiber products have also been developed as reinforcing materials.

(2) Inorganic substrate insulation paper – using inorganic glass fiber cloth, alkali-free glass fiber mat and the like as reinforcing materials. Long-term use temperature is 130~180 °C, even higher temperature, depending on the binder resin.

Laminate plastic articles are classified into laminates, laminates, laminates, and molded laminates by shape and use. Copper-clad laminates for printed circuits and adhesive-capacitor sleeves for capacitive bushings for high-voltage electrical appliances are two special types of laminated plastic products.