Domestic status of transformer industry

China’s transformer manufacturing industry is an industry full of opportunities and challenges. As long as the technology content is continuously improved to meet the user’s requirements for safe, stable and reliable operation, the market price of customer service raw materials and the market pulse will be the winners.

To continuously improve the product structure, reduce losses as much as possible, and produce high-quality products on the premise of ensuring high efficiency, we must work hard on product development.

Limited by theories and calculation methods in the past, the problem of product reliability has not been solved well. For example, the magnetic leakage loss and local overheating of the product cannot be effectively solved. With the development of the power industry in the direction of high voltage and large power grids, the safety and reliability of equipment has become the prerequisite for users to choose products, so the goals of optimization calculations should also be adjusted at any time.

China’s key scientific and technological projects during the “Seventh Five-Year Plan” period have also invested considerable human capital in research to reduce additional losses in transformers and prevent local overheating.

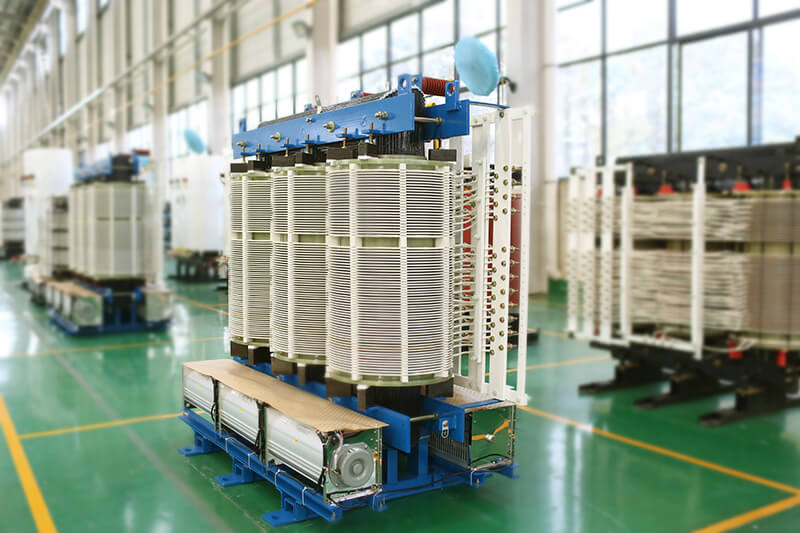

The domestic transformer industry has uneven development in calculation software. Several manufacturers producing transformers of 220kv and above,such as ZTELEC have strong scientific research capabilities. They started early in this area and in their early years Introduced electromagnetic calculation software, wave process analysis software, and leakage magnetic field analysis software from ALSTHOM, Japan’s Hitachi, Sweden’s ABB, Germany’s Siemens, etc. In the product design, the calculation part is completed on the computer. According to the needs of different products, it can complete the important electromagnetic indicators such as wave process, ampere balance check, magnetic flux leakage distribution and calculation of thermal field, etc.

Intensified market competition and soaring raw material prices place higher demands on product quality and delivery time. In recent years, the in-depth application of finite element analysis methods, detailed analysis of the electric field and magnetic field of transformers, and on the basis of summing up the previous application experience, have the conditions to incorporate mature scientific research results into the development of transformer optimization software.