CCL is Mainly Used for the Manufacture of Printed Circuit Boards (PCB)

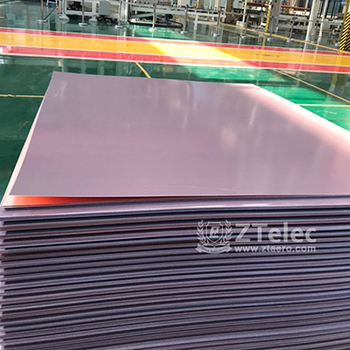

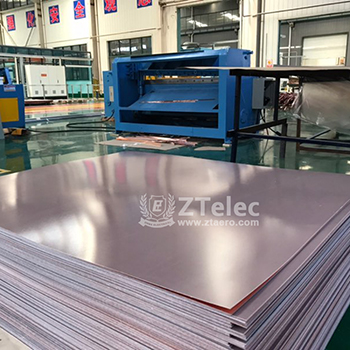

CCL (full copper clad laminate, English referred to as CCL), is made from wood pulp paper or glass cloth as reinforcing material, impregnated with resin, single-sided or double-sided coated with copper foil, a product formed by hot pressing.

The copper clad plate is the basic material of the electronics industry. It is mainly used for manufacturing printed circuit board (PCB). It is widely used in electronic products such as TV, radio, computer, computer, mobile communication and so on.

The copper clad plate industry has a history of nearly 100 years. It is a technology development history that is synchronized with the electronic information industry, especially with the PCB industry. The development of the copper clad plate began in the early twentieth Century. At that time, the manufacture of resins, reinforced

materials and substrates for copper clad laminate has made encouraging progress, such as:

In 1909, Dr. Bakeland developed and applied phenolic resin.

In 1934, Sch Lake, Germany (Schlack) synthesized epoxy resin from bisphenol A and epichlorohydrin.

In 1938, Owens Corelle glass fiber company began to produce fiberglass.

In 1939, Anaconda company of the United States pioneered the production of copper foil by electrolysis.

The development of the above technologies has laid an important foundation and created the necessary conditions for the development of CCL. Since then, with the invention and application of integrated circuits, the miniaturization and high performance of electronic products have promoted the further development of CCL technology and production. With the rapid development of multi-layer laminating technology (Buildup Multilayer), many new substrate materials such as resin coated copper foil (RCC) appear.