Bakelite with Low Raw Material Prices and Excellent Product Characteristics

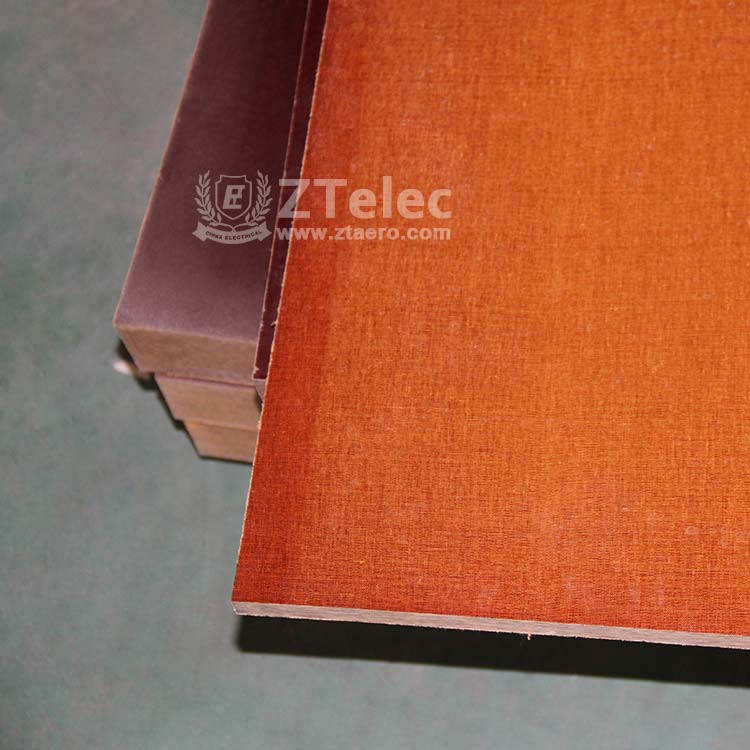

Electric wood board is also commonly known as phenolic laminated paperboard, rubber board, and phenolic board. It is reinforced with high-quality bleached wood paper and cotton velvet paper, and then is made of high-purity synthetic petrochemical raw material phenolic resin as a resin. Made. The main material is a chemical substance synthesized by hand. If it is heated, it will not be shaped into other shapes. After molding, it has the characteristics of non-conductivity, high temperature resistance, non-absorption, high strength, and is basically applied to the electric field in the field of electrical appliances.

The main characteristics of the electric board commonly used in the market are intermediate electrical insulation wire, anti-static, good mechanical strength, high mechanical strength, electrical insulation, zero insulation, and oil resistance. It can also be used in the PCB industry as a pad for drilling, fixture board, packaging machine, mold splint, distribution box, high and low voltage wiring box, can be used as motor mold, mechanical mold, ICT fixture, countertop, grinding pad, forming drill.

Bakelite products are the first choice for many plastic products because of their low raw material prices and excellent product characteristics. The price of bakelite raw materials is close to 50% of the ABS price. Although Bakelite products are heated and formed during molding, the processing time is longer than that of ordinary plastics. The wear of the molds is relatively high, and the demand for steel is high. However, due to the superiority of raw material prices, it is still the preferred substitute for many plastic parts.