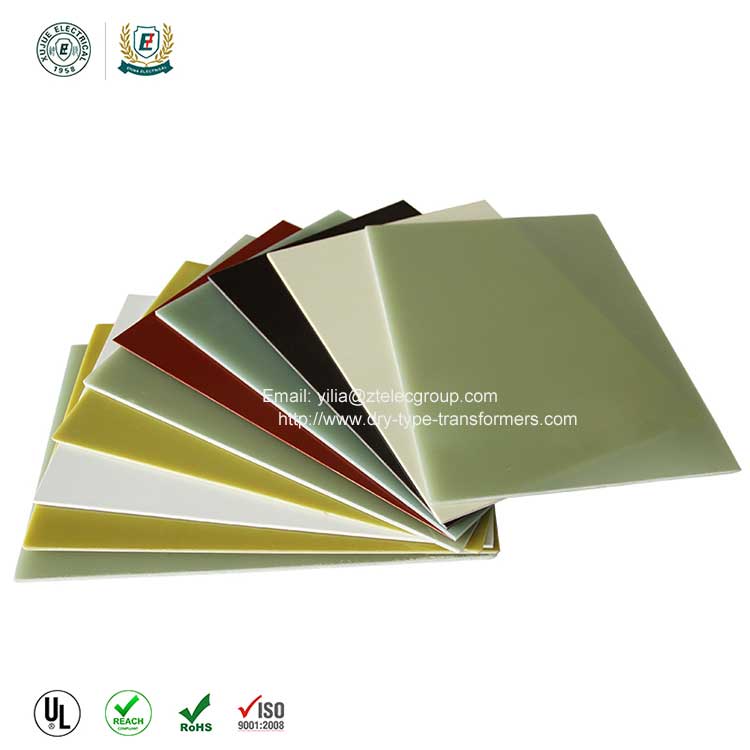

Application Characteristics of Epoxy Board Processing for Transformers

Various forms.

Various resins, curing agents, and modifier systems can be adapted to the requirements of the form for a variety of applications, ranging from very low viscosity to high melting point solids.

Easy to cure.

Epoxy resin system can be cured in the temperature range of 0-180 °C by using various curing agents.

Strong adhesion.

The presence of polar hydroxy[1] groups and ether linkages inherent in the epoxy resin molecular chain provides high adhesion to a wide variety of materials. When the epoxy resin is cured, the shrinkage is low, and the internal stress generated is small, which also contributes to an improvement in adhesion strength.

Low shrinkage.

The reaction of the epoxy resin and the curing agent used is carried out by a direct addition reaction or a ring-opening polymerization reaction of an epoxy group in a resin molecule, without the release of water or other volatile by-products. They exhibit very low shrinkage (less than 2%) during curing compared to unsaturated polyester resins and phenolic resins.

Mechanical properties.

The cured epoxy resin system has excellent mechanical properties.

ZTELEC GROUP is steadily growing up into a leading enterprise of electrical equipment with an international brand in China. We are ISO9001, ISO14001 and OHSAS18000 certified. ZTELEC GROUP specializes in insulating laminates, insulating composite products and transformer insulation materials. Various specifications of insulation materials can be customized according to customer requirements.